Red Dot Design Award

The internationally acclaimed Red Dot Design Award acknowledges excellence in design. Formal quality, functionality and innovation are some of the criteria that mark out the excellent design quality of this product.

Attributes

Details

Accessoires / Service

1 pce.

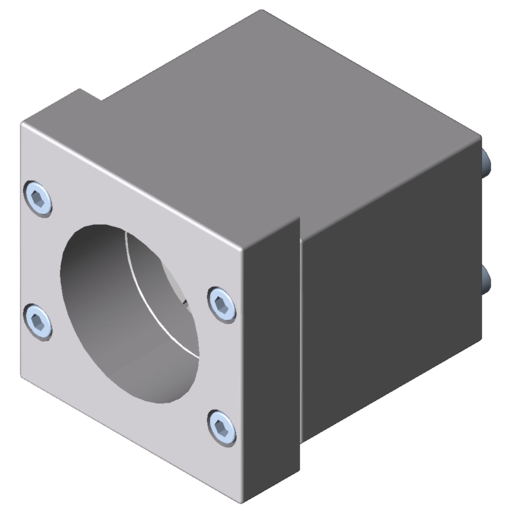

0.0.612.75

1 pce.

0.0.612.74

1 pce.

0.0.609.31

1 pce.

0.0.604.41

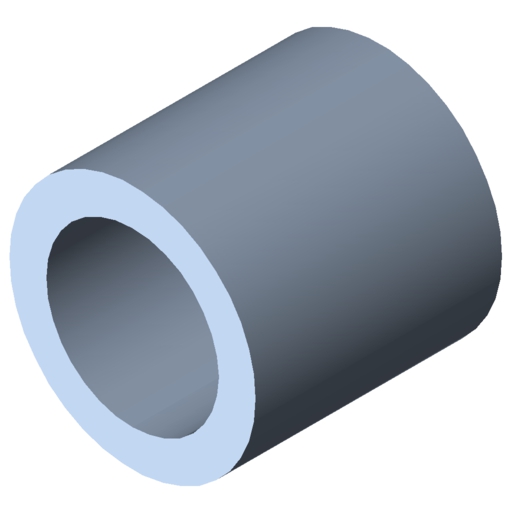

1 set

0.0.609.25

1 set

0.0.609.80

1 set

0.0.609.81

cut-off max. 6000 mm

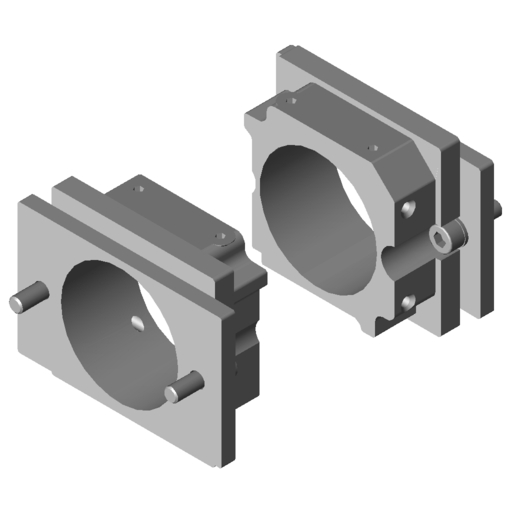

0.0.609.86

1 set

0.0.612.46

Downloads

Deflection calculator

Load 1

Load 2

Load 3